Description

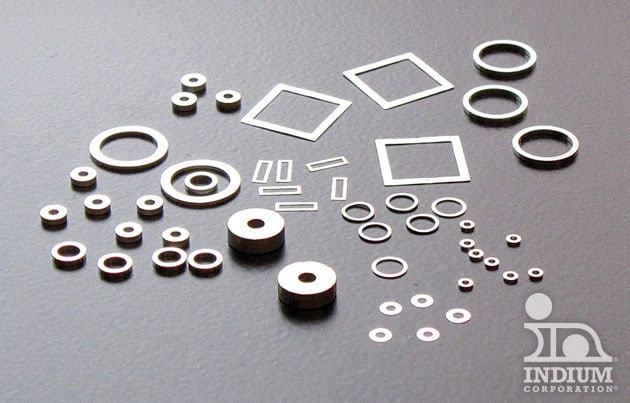

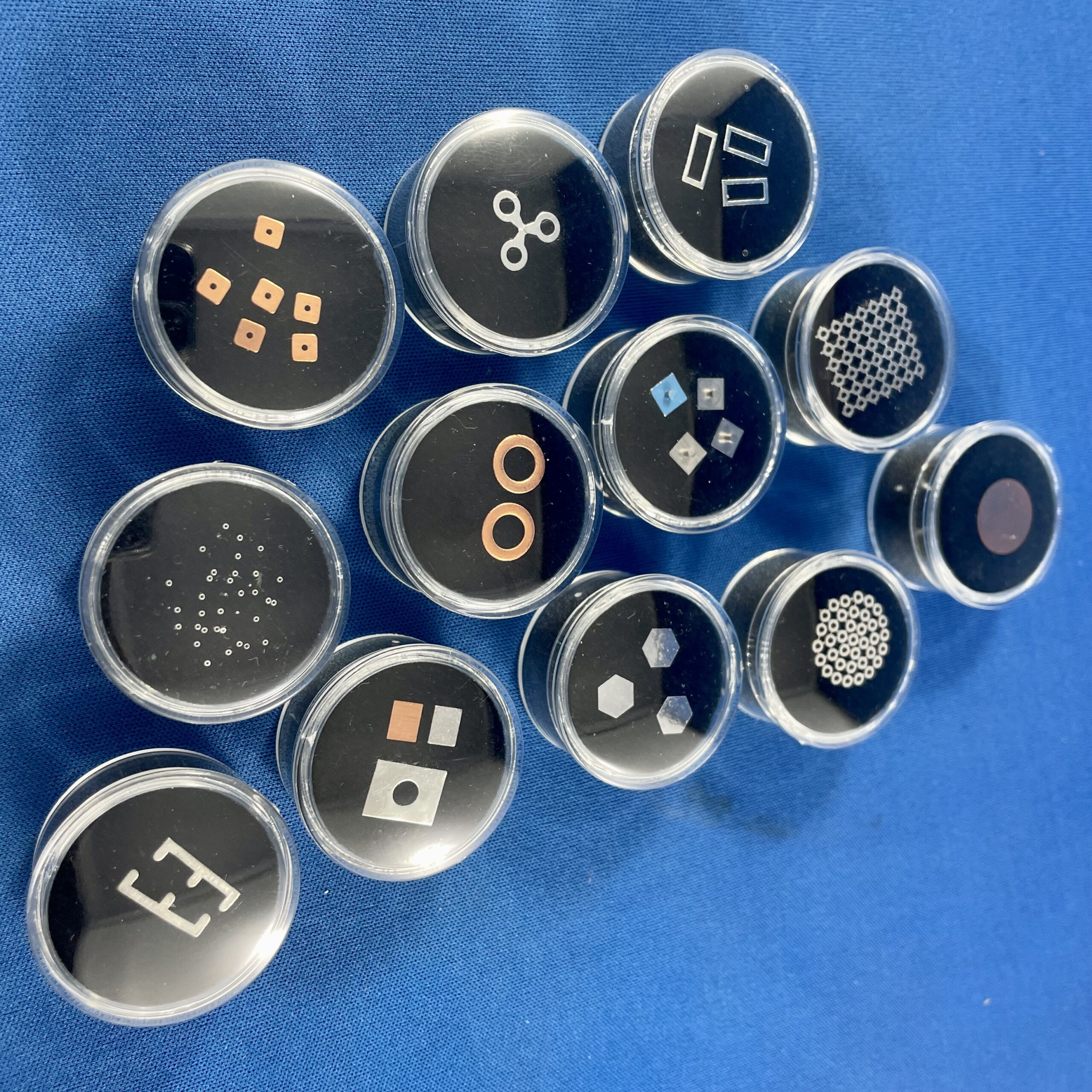

Solder Preforms

The use of Solder Fortification Preforms will add more solder volume and help obtain the correct amount of solder therefore ensuring a much strong solder joints. This is particularly useful in situations where there is reduced stencil thickness, such as those with a pitch of 0.3mm or less or where there are tightly fitted components, which is now becoming the norm within the SMT industry as the miniaturization trend shows no signs of slowing.

Solder preforms are generally rectangle or disc shaped pieces of alloyed metal that do not contain any flux. Since the alloy for both the preform and paste are the same, the preform reflows at the same temperature as the paste and the paste in turn provides the necessary flux. The preform increases the volume of solder above that of the paste alone.

SMT Industrial offers a wide selection of shapes and sizes of solder preforms.

Contact us for available sizes and pricing.

Features:

- Increased Solder Volume

- Stronger solder joints for improved drop test results

- Fewer issues with flux residue

- Reduced Rework

- Improved fillet shape and volume ensures joints meet IPC specifications

Common Alloys: SAC 305, SAC 387, Sn63, Sn62, BiSn, BiSnAg

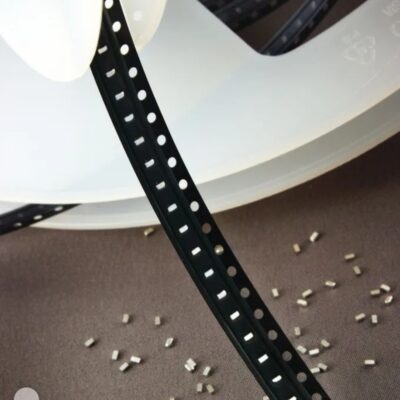

Solder Preform Sizes:

|

Name: |

Size: |

Quantity per 7” Reel |

Quantity per 13” Reel |

Example Weight SAC 305 (Grams/Each) |

|

0201 |

.010” x .020” x .010” rectangle |

1k |

50k |

.00024 |

|

0402 |

.020” x .040” x .020” rectangle |

1k |

15k |

.00182 |

|

0603 |

.030” x .060” x .030” rectangle |

1k |

15k |

.00672 |

|

0805 |

.050” x .080” x .050” rectangle |

1k |

15k |

.02410 |

Download Our Solder Fortification Design Guide: Solder Fortification Guide

Reviews

There are no reviews yet.