DRY CABINET APPLICATIONS IN A PRODUCTION ENVIRONMENT

DESICCANT CABINET APPLICATIONS IN HUMIDITY CONTROL

The number of opportunities for moisture related production faults can be reduced with the use of dry storage cabinets.

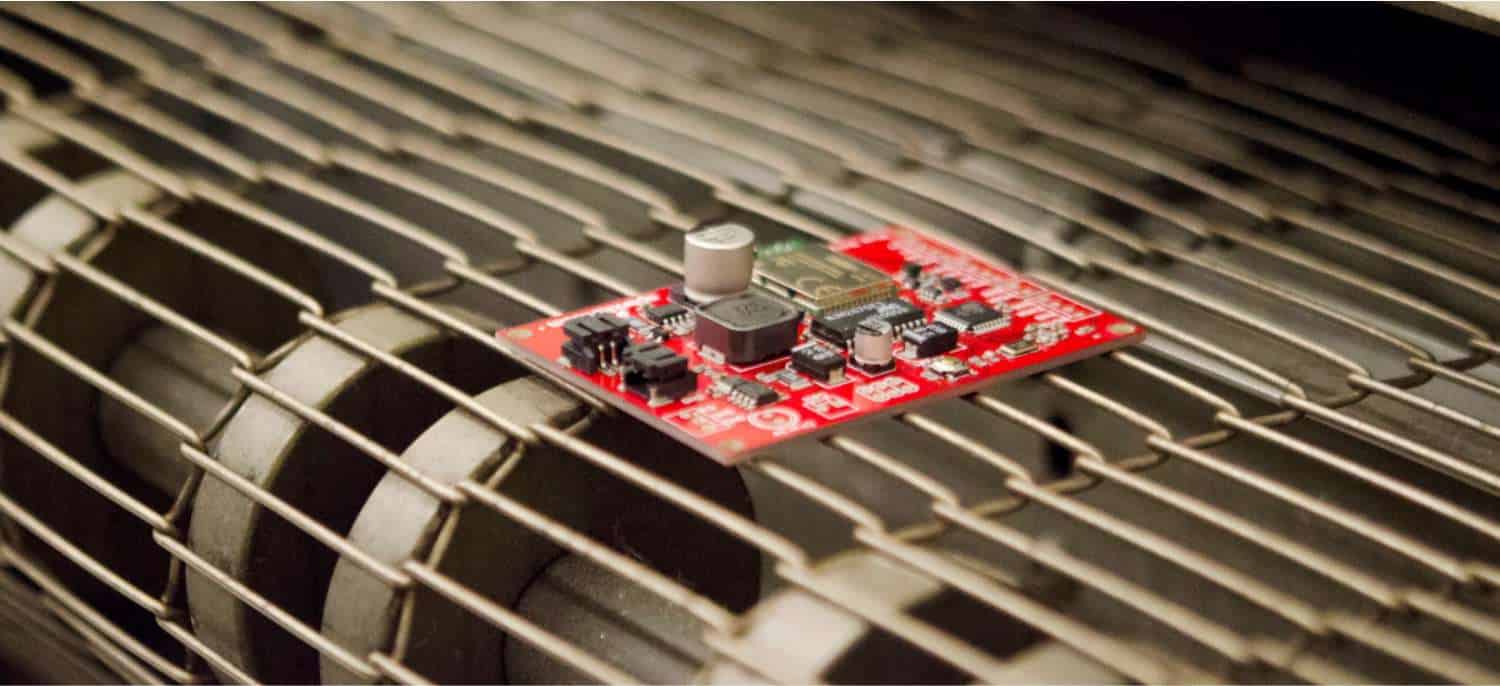

- Active Devices

Reduce moisture related damage to all types of active devices from PoP, Stacked Die, BGA, QFP, etc.

- Passive Components and Connectors

Prevent solder defects by reducing the potential for oxidation of leads caused by excessive moisture during storage and kitting

- Circuit Boards

Maintain accurate board dimensions with humidity controlled storage reducing board stretch and warp due to high moisture content

- Ceramic and Blue Tape

Protect substrates and base materials from high moisture content

- Silicon Wafers

Reduces contamination potential from particulates suspended in moisture droplets with a humidity controlled environment

- Lead Frames & Carriers

Controlled humidity increases the reliability of solder and wire bond points with reduced potential for oxidation

- Fiber Optics

Retards organic growth and maintains the condition of key fiber optics devices and components with a controlled environment.

- Specialized Glass & Displays

Provides a controlled environment between process steps for switchable glass (LCG) components

For more information see: SMT Dry Boxes Website

Have Questions?

Please feel free to contact us any time with questions or for more information about the products on our website. Or fill in the form below with any questions you have and we will get back to you as soon as possible.